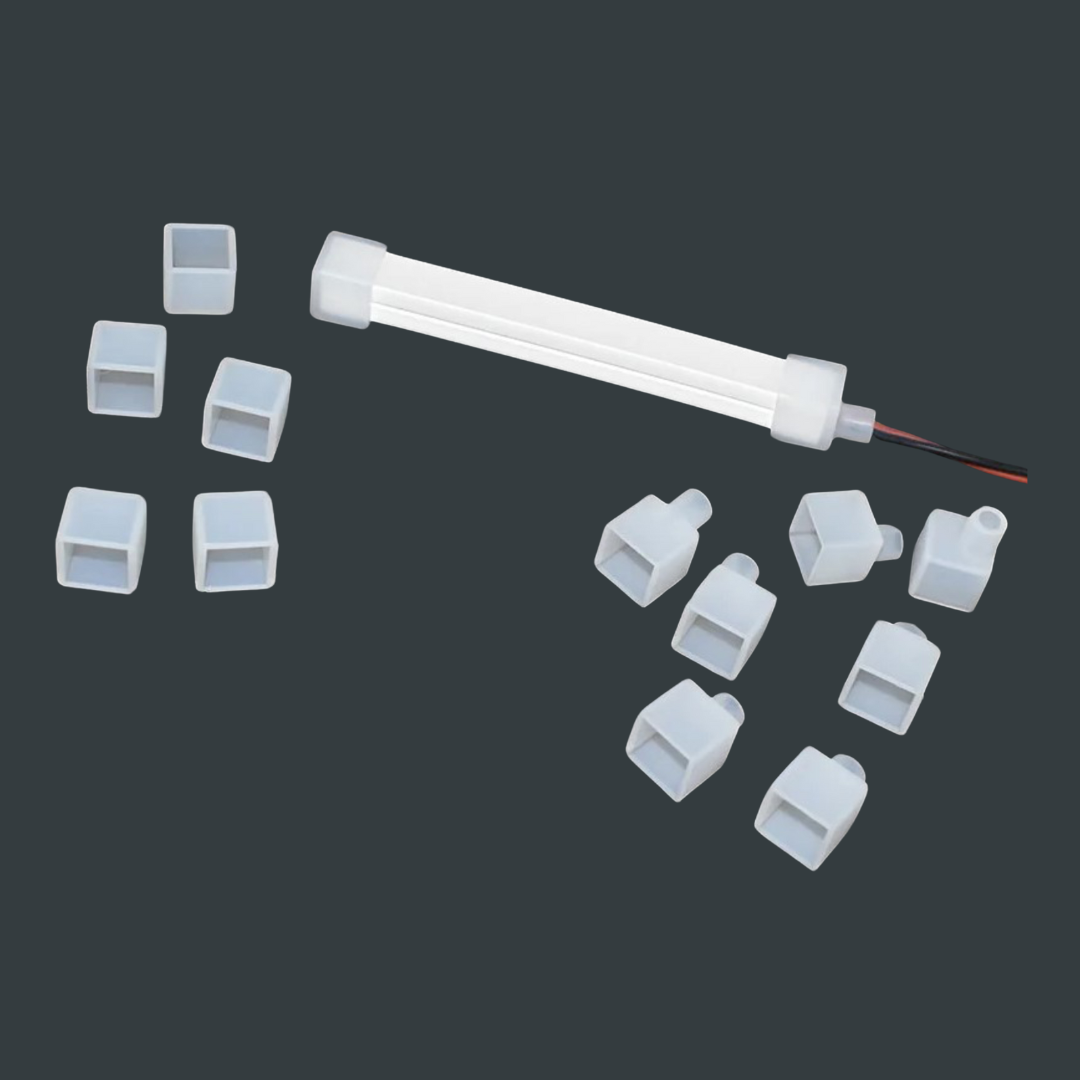

LED Silicon End Cap

Keep Your LED Strip From Moisture and Damage With LED Silicon End Cap. Easy to install and versatile they’re a Have For any Lighting Project.

Everything You Need to Know About LED Silicon End Caps: A Comprehensive Guide

In the realm of LED lighting solutions, every component plays a crucial role in ensuring optimal performance and longevity. Among these components, the LED silicon end cap stands out as a critical element that not only protects the LED strip but also enhances its functionality. In this comprehensive guide, we delve into the intricacies of LED silicon end caps, exploring their features, benefits, installation methods, and more.

What are LED Silicon End Caps?

LED silicon end caps are small yet significant components designed to seal and protect the ends of LED strips. Made from high-quality silicon material, these end caps provide a barrier against moisture, dust, and other environmental factors, safeguarding the delicate LED components within. Additionally, they help maintain the structural integrity of the LED strip, preventing any potential damage or wear over time.

Features of LED Silicon End Caps:

- Waterproof Properties: One of the primary features of LED silicon end caps is their waterproof nature. This attribute makes them ideal for outdoor applications where exposure to moisture is a concern. Whether it’s rainy weather or humid conditions, these end caps ensure that your LED strips remain fully protected.

- Flexible and Durable: Silicon material offers both flexibility and durability, allowing the end caps to withstand bending, twisting, and other forms of mechanical stress. This flexibility is particularly advantageous when installing LED strips in tight or unconventional spaces, ensuring a snug fit without compromising on performance.

- Heat Resistance: LED silicon end caps are also known for their excellent heat resistance properties. As LED strips generate heat during operation, especially at higher brightness levels, it’s essential to have end caps that can withstand elevated temperatures without deforming or deteriorating. The silicon material used in these end caps excels in this regard, ensuring reliable performance even in demanding thermal conditions.

- UV Stability: Exposure to ultraviolet (UV) radiation can degrade the materials used in LED lighting systems over time. However, LED silicon end caps are engineered to resist UV damage, maintaining their integrity and prolonging the lifespan of the LED strips they protect. This UV stability ensures consistent performance and aesthetics, even in outdoor environments with prolonged sun exposure.

- Easy Installation: Installing LED silicon end caps is a straightforward process that doesn’t require specialized tools or expertise. These end caps typically feature a simple design with slots or channels that accommodate the LED strip, allowing users to quickly and securely seal the ends without any hassle.

Benefits of Using LED Silicon End Caps:

- Enhanced Protection: By effectively sealing the ends of LED strips, silicon end caps provide enhanced protection against moisture, dust, debris, and other environmental factors. This protection not only extends the lifespan of the LED strips but also ensures consistent performance in various conditions.

- Reduced Maintenance: LED silicon end caps help minimize maintenance requirements by shielding the vulnerable ends of LED strips from potential damage. With fewer concerns about moisture ingress or physical wear, users can enjoy greater peace of mind and lower maintenance costs over time.

- Improved Aesthetics: In addition to their functional benefits, LED silicon end caps contribute to the overall aesthetics of LED lighting installations. By neatly concealing the cut ends of LED strips and providing a clean finish, these end caps enhance the visual appeal of the lighting arrangement, creating a polished and professional look.

- Versatile Applications: LED silicon end caps are suitable for a wide range of applications, including architectural lighting, signage, accent lighting, and more. Whether indoors or outdoors, residential or commercial, these end caps offer versatility and reliability, making them indispensable components in LED lighting projects of all scales.

Installation Methods for LED Silicon End Caps:

- Preparation: Before installing LED silicon end caps, ensure that the LED strip is clean, dry, and free from any debris or contaminants. Trim the strip to the desired length, making precise cuts to achieve a neat finish.

- Insertion: Slide the LED strip into the designated slot or channel of the silicon end cap, ensuring a snug fit. Make sure that the strip is positioned flush with the end of the end cap for optimal sealing.

- Sealing: Apply a small amount of adhesive sealant or silicone caulk to the inside of the end cap to create a watertight seal between the strip and the cap. Press the end cap firmly onto the end of the LED strip, ensuring uniform contact along the entire length.

- Curing: Allow the sealant or caulk to cure according to the manufacturer’s instructions before handling or powering the LED strip. This curing process ensures a secure bond and maximum effectiveness of the sealant.

- Testing: Once the installation is complete, conduct a thorough inspection to ensure that the end caps are securely in place and that there are no gaps or leaks. Test the LED strip to verify proper functionality and ensure that the end caps have not impeded the light output in any way.

In conclusion, LED silicon end caps play a vital role in protecting and enhancing the performance of LED lighting systems. With their waterproof properties, flexibility, durability, and ease of installation, these end caps offer a comprehensive solution for sealing the ends of LED strips in various applications. By understanding the features, benefits, and installation methods of LED silicon end caps, users can make informed decisions to optimize the efficiency, longevity, and aesthetics of their LED lighting projects.